engineered oak flooring

-

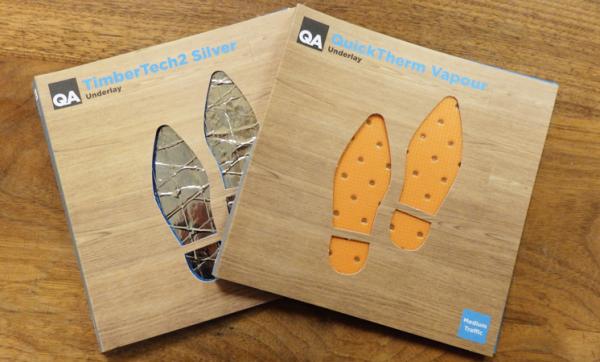

Floating Solid and Engineered Wood Flooring

Our customers often ask advice about the best way to fit the wood flooring that they have bought from us. The advice we offer can vary depending on the type of flooring purchased and also what the customer is fitting the floor onto (the subfloor). This mini guide offers guidance for floating our own solid and engineered wood floors. The...